Custom 3D Printed Baby Gate Molding Adapters or Why 1 Billion Dollars Can’t Buy You Everything, Unless…

Throughout my career, especially while working in Hollywood and raising capital, I’ve had the privilege of being hosted by a number of affluent individuals—successful business people with net worths in excess of $1B USD.

On one of these occasions, I was hosted at a breathtaking seaside mansion abroad. Picture awe-inspiring views of the water, a spectacular pool, incredible architecture, and coffee appliances costing tens of thousands of dollars. My host had artwork and sculptures rivaling a museum. Winding throughout the house were gorgeous marble Italian moldings at the base of the walls. While admiring all of the beauty, I noticed a winding staircase in a multi-story (of course) foyer. That staircase led to another staircase that descended to a lower level, maybe to the batcave.

Then, what did I see at the top of this elegant staircase?

Baby gates.

The same damn $75 Dreambaby baby gates that block the top of the staircase at my house.

You can spend $12,000 on a cappuccino machine if you can afford it, but as it turns out, money can’t buy a better baby gate.

The difference between my house and this house? Here, the ornate Italian moldings had been destroyed to accommodate the baby gates. The moldings had been drilled into and cut so that the baby gate could hold flush against a flat surface.

Parents are all too familiar with this design flaw. Baby gates do not accommodate baseboards. The only way to safely secure a baby gate? Destroy your house. Who does the manufacturer think they’re making these baby gates for? Who the hell has flat walls all the way down to the floor?

So there you have it: the special billionaire baby gate upgrade you’ve been Googling over this past year just doesn’t exist (you’re welcome). There are no better baby gate options on the market than the ones we’re all stuck with. Billionaires included.

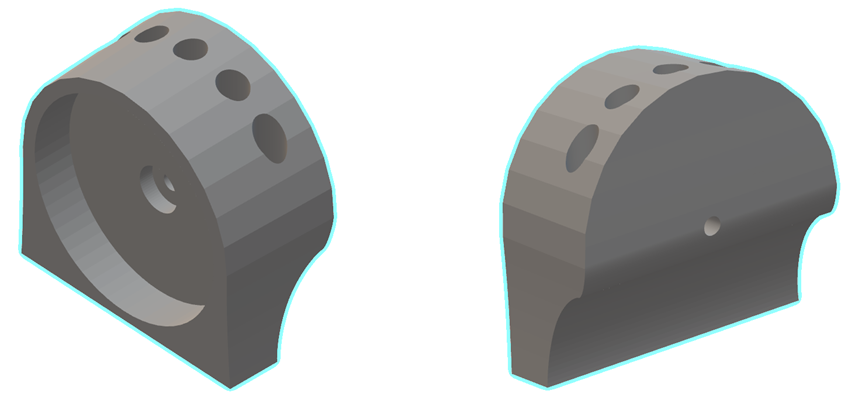

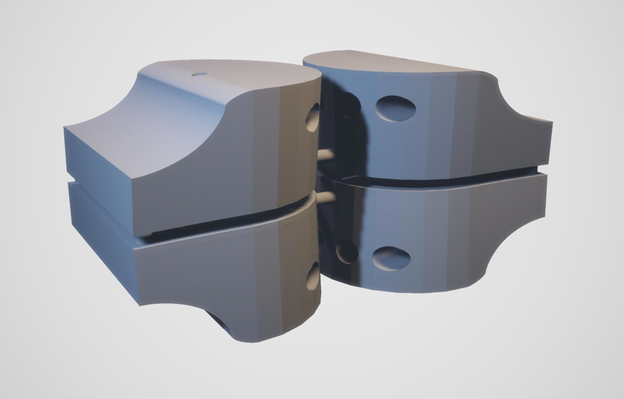

Except at MY house, where the moldings are perfectly intact and the baby gates hold securely. I conquered the molding dilemma through one of my favorite hobbies, 3D printing. I traced the shape of the baseboard with a piece of paper, scanned it into a computer, and created a baby gate molding adapter design in 3D Studio Max. BOOM. Problem solved. To this day, the baby gate fits perfectly against this custom 3D printed adapter. My baby gates are firmly attached, without causing any damage, and when I remove them, no one will ever know they were there.

Figure 1: I traced the moldings and the baby gate clamp with a pencil and paper and scanned it in.

Figure 2: The 3D Model. The “Speed Holes” reduce the amount of plastic needed to reduce printing cost.

Figure 3: Packing them together into one object to further reduce volume and 3D printing cost.

Figure 4: The final result…installed!

So, moral of the story: Money can’t buy you everything—unless you have a 3D printer.